In the Nexus of Heat Wave Risks: Iron oxide primer coating of corrugated iron roofs for space cooling

In the Nexus of Heat Wave Risks: Iron oxide primer coating of corrugated iron roofs for space cooling

Nadim Reza Khandaker, Ph.D., P.Eng., Arup Ratan Das, North South University Bangladesh

Corresponding Author email: nadim.khandaker@northsouth.edu

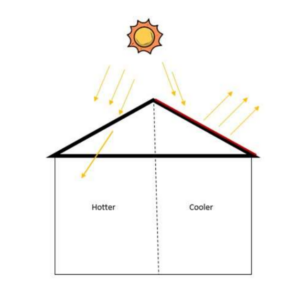

The effect of global warming has manifested it self as more intense heat waves. This is more of a problem in rural and urban setting in resource constrained communities that exists in Bangladesh a country in South Asia. Housings in urban slums and many rural communities are either completely constructed with corrugated iron sheets or even the ones constructed with brick and motor have corrugated iron sheet roofs (Figure 1). Locally referred in Bangladesh as wave tin (Dehaw Tin), are iron sheets that are processed to make wavy and dipped in molten aluminum to rust proof. These sheets have high absorptivity for solar radiation and have low heat emissivity. Thus, they become really hot in direct sunlight and transmit the heat to the indoor space when used for wall and roof construction. The indoor temperature of corrugated iron sheet constructed shack housing become high during hot summer days and specially during a heat wave, leading to thermal shock of the inhabitants and even mortality unless mitigation measures are taken. Common mitigation measures call for use of mechanical cooling and ventilation systems that in the context of resource challenged communities an expensive proposition. Compounding this is the unreliability of electric power and disruption of power supply commonly referred to as load shedding in developing economies and would make mechanical mitigation measures inoperative. Passive mitigation measures be it heat insulating the corrugated iron sheets or even painting the corrugated iron sheets using-heat insulating paints (Figure 2) are more prudent options (1).

Figure 1: An urban slum housing completely constructed with corrugated iron sheets in Rangpur Bangladesh that experiences frequent heat waves.

Figure 2: Simple illustration of passive mitigation measure of painting the corrugated iron sheets using-heat insulating paints and how it functions to keep interior space cool.

In search of a locally sustainable solution an action research program was undertaken that looked at passive heat resistant solution using locally available iron oxide rust proof coating paint. Separate corrugated iron sheets of similar dimensions were painted with iron oxide rust proof coating and their heat insulating capability was compared to unpainted corrugated iron sheets (Figure 3).

Figure 3: Action research program was undertaken that looked at passive heat resistant solution using locally available iron oxide rust proof coating paint.

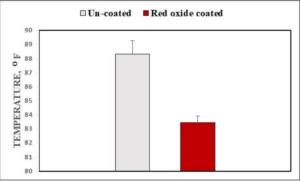

The experimental program was conducted during mid-day summer heat. The temperature on both the surfaces of the corrugated iron sheets were measured to determine their heat reflection and emissivity. Corrugated iron sheets with red oxide rust proof coating transferred least amount of heat resulting in lower temperature in the bottom surface of the corrugated iron sheets (Figure 4). The inference being that roofs painted with iron oxide rust proofing serves as a barrier to heat transfer to the space below by the combined mechanism of lowering absorptivity for solar radiation and serving as an insulation for heat transfer to the interior space.

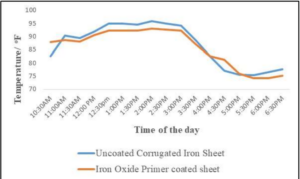

A field trail on two poultry sheds, one coated with red oxide paint and the other unpainted showed that coated corrugated iron shed experienced temperatures 2oF- 4oF less throughout the day. Also, the red oxide coated shed emitted heat more gradually (Figure 5) ensuring more tempered indoor climate is maintained. This mitigation is simple, protects against rusting and controls temperature in indoor space. Application is not limited to human habitats such as slum housing but also to animal husbandry where poultry and animals need protection against heat stress.

This is critical for the small-scale poultry operator because during the recent heat spell the poultry was experiencing greater than usual mortality of the birds due to heat shock. A few degrees lowering of temperature can substantially cut down on the bird mortality. This would be beneficial for the small-scale rural poultry farmers. Happy to note that the mitigation measure has caught on locally where we tried our first field trial. The challenge now is to promote the simple mitigation strategy to combat against extreme heat events to the greater stake holders in the resource constrained world.

Figure 3: Field trail on two poultry sheds, one coated with red oxide paint and the other unpainted.

Figure 4: Graph of the indoor temperature trend for the field trail on two poultry sheds, one coated with red oxide paint and the other unpainted.

- Peng, Y., Lai, J., Xiao, X., Jin, W., Zhou, J., Yang, Y., Gao, X., Tang, J., Lu, F., Fan, S., Bao, Z., & Cui, Y., Colorful low-emissivity paints for space heating and cooling energy savings. Proceedings of the National Academy of Sciences of the United States of America, 120(34) (2023).

Acknowledgements

The research team members were Arup Ratan Das and Tasriba Karim Sayanno, undergraduate students and was supervised by Professor Nadim Khandaker, from Civil and Environmental Engineering North South University, Bangladesh and Associate Professor Sebha Saleem Department of Arts and Architecture in Sushant University, India.